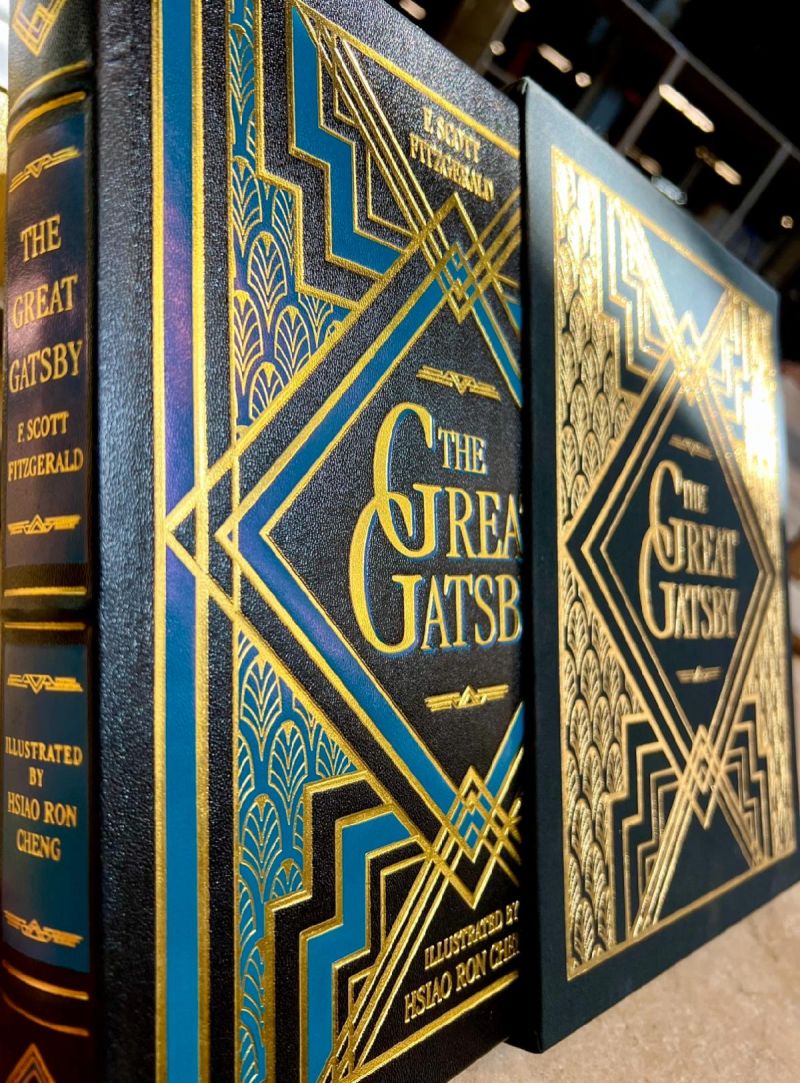

Elevate your project with the artistic embellishment of a book’s cover or spine to enhance its visual appeal, distinguishing it as a work of art.

Foil stamping is a process that uses pressure and heat to apply a colored foil to a substrate.

Raised, horizontal bands or ridges on the outside spine of a casebound book.

A technique that utilizes a die to press a design, text, or image into the back of a substrate – creating a raised effect when looking at it from the front.

A technique that utilizes a die to press a design, text, or image into a substrate – creating a recessed effect.

A decorative, protective cover that wraps around the outside of a casebound book.

Rounding off the sharp, right-angled corners of a book’s cover or pages, instead of leaving them square.

Attaching a decorative page, medallion, or object.

Hot stamping a pattern or design into the material which leaves the fine, crisp, darker notation of the die.

A narrow band of elastic rubber used to keep you book closed.

A narrow strip of material attached to the spine to mark a page in the book. Ribbons come in various color, lengths and textures (grosgrain, double sided satin, 1 side of each).

A solid colored die that can be sprayed on the head, foot, and face of your book. Stains can be PMS matched and work best on uncoated stocks.

CMYK digitally printed names/scenes/images directly onto the head, foot, and face of your book. This process can be done on both coated and uncoated stocks.

Applying a thin layer foil to the head, foot, and face of the text block. This process can be done on both coated and uncoated stocks.

A casebound book with a cover made from three pieces of cover material. Typically, the front and back cover will utilize the same material with the spine having a contrasting cover material.

Ask your CSR for our list of exotic materials, genuine leathers, or show us what you have in mind!

Lamination and Spot UV can provide a 3D rubbery feel to elements on your design

Considered the creme de la crème, these silk endsheets shimmer in light to create a premium luxurious appearance.

Cutting a substrate using a set of dies (or a laser) to create an image, design, name, or pattern.

Tabs (protruding or intruding sections of paper) and step indexing (cut outs in the face) refer to protruding sections of paper, typically found along the edge of a page, that are used to mark specific sections or provide easy access to different parts of a book.

Stamping – the rougher the substrate the less detail you are going to be able to achieve.

Crucial to prevent the pages of the book blocks and end sheets from wrinkling. They should be printed with the grain running parallel to the spine. Grain of text should run parallel to binding edge. And can provide cost savings!

– Raw board covers – Flush cut covers – French fold book blocks – Exotic materials

Shrink wrap your decorative covers, specifically for books with stamping and abrasive materials, to ensure quality.

Gilding uses pigmented or metallic foil. Edge printing uses CMYK. Staining uses PMS matching.

Choosing a text stock is imporant! Ask yourself: – Can it be sewn? (too thick or thin to sew) – Will it lay flat? – Glue/text combo (white glue – uncoated)

Can I have a cover template?

Yes! Once you finalize the project specifications finalized and submit your purchase order, our team can produce a cover template for you to base your design on. This template will be set to your customized project’s measurements, binding, and cover style.

Can multiple paper types be used with text stock?

Yes, however it is crucial that the text/ signatures are folded the same way.

Differences between embossing and debossing?

Both techniques add texture to the cover, but embossing gives a 3D effect, while debossing adds subtle depth.

Are you ready to craft your vision? Send us your project specifications and let’s get started!

Request A Quote